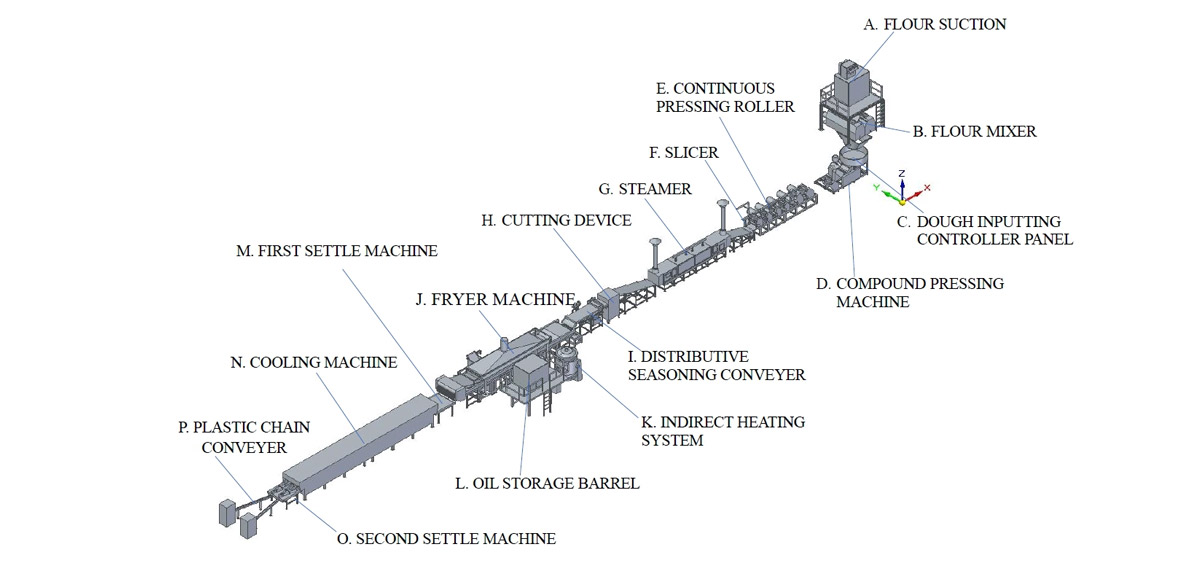

Automatic Instant Noodle Production Line

- Making Processing:

Mixer→Compound→Continuous Pressing→Steaming→Frying→Cooling- Using Flour Mixer to mix salt, water, flour and other formulas evenly.

- Dough dropped into the Compound Pressing Machine to produce dough sheet and make it more flat and solid.

- Passing the dough sheet to Continuous Pressing Roller to press from thick to thin.

- The final roller with slicer to cut the dough sheet to become noodle strips and make waving.

- Waving noodles are steamed to finalize the noodle shape.

- Then, cutting and folding the noodle to become noodle cake and delivering to Fryer Machine.

- After frying, delivering the noodle cakes to Cooling Machine and can be packed.

- Special Function:

- Roller:Each roller has independent motor, and using inverter to control speed.

- Steamer:Using exhaust hoods to reduce steam leakage.

- Fryer Machine:Oil removing windmill to reduce oil content of noodle cakes.

- Cooling Machine:Using hot fan to cool down the temperature of noodle cakes which after frying.

- Safety Device:Each roller is equipped with the sensor to sensing dough passing;The whole machine is equipped with emergency stop button.

- All product contact surface area is stainless steel or food grade material.

- Dough Inputting Controller